WuXi Biologics Achieves Milestone in 2,000L Drug Substance Production

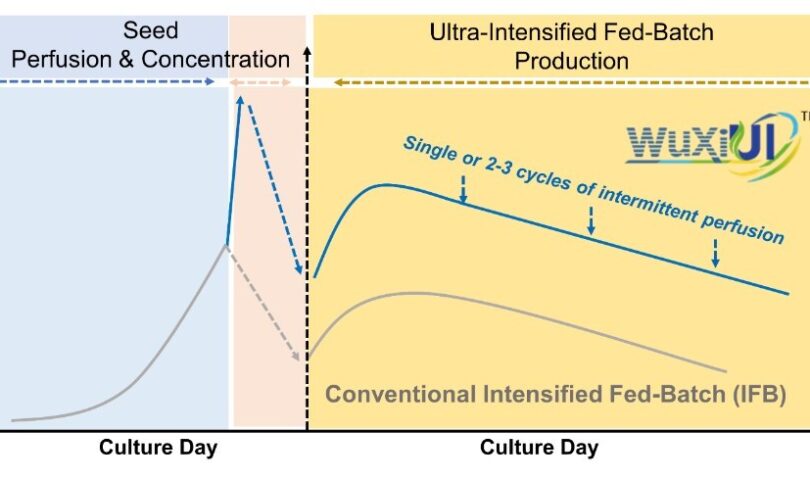

WuXi Biologics, a leading Contract Research, Development, and Manufacturing Organization (CRDMO), recently announced a significant achievement in biologics manufacturing. Through the utilization of its ultra-intensified fed-batch bioprocessing platform, WuXiUI™, the company successfully completed its first scale-up to 2,000L drug substance (DS) GMP production. This milestone marked a 4-fold increase in productivity compared to conventional fed-batch methods.

The enhanced efficiency delivered by WuXiUI™ and the proprietary platform cell culture media, MagniCHO™, resulted in substantial cost savings in overall DS production. The platform’s consistent performance, from small-scale operations to large-scale GMP production, demonstrates its maturity and robustness in significantly improving the cost-effectiveness of biologics manufacturing.

The successful scale-up to 2,000L DS production showcased WuXiUI™’s capability to achieve a titer of 18 g/L, highlighting its efficiency in enhancing productivity. Additionally, WuXi Biologics’ downstream production platform enabled doubled purification processing capacity, leading to a 50% reduction in processing time and a final DS yield of 70% with consistent product quality. The downstream platform also contributed to a 30-50% reduction in material and consumables usage, resulting in decreased waste generation and lower production costs.

The WuXiUI™ platform, introduced in 2023, has proven to be highly effective in enhancing productivity across various CHO and alternative mammalian cell lines while maintaining desired product qualities. It offers a cost-effective solution for global clients to meet the growing demand for therapeutic proteins and antibodies. Furthermore, the platform’s efficiency contributes to a reduced carbon footprint due to its optimized media consumption, reduced waste generation, and minimized facility space requirements.

The successful application of WuXiUI™ was further enhanced by the use of MagniCHO™, WuXi Biologics’ proprietary cell culture media enriched with nutrients for intensified processes. Integration of the Raman Process Analytical Technology (PAT) system into the scale-up production process improved operational efficiency and production robustness, enabling real-time automated process control under GMP conditions.

Dr. Chris Chen, CEO of WuXi Biologics, commented on the achievement, stating, “The successful application and achievement of WuXiUI™ is a result of our relentless pursuit of technology innovation to accelerate biologics development while achieving cost efficiency for global clients. With this milestone, we have enhanced our capabilities to enable clients to bring more affordable, high-quality biologics to market, benefiting patients worldwide.”

WuXi Biologics continues to lead the way in biologics development and production, offering end-to-end solutions for partners worldwide. With a focus on innovation, efficiency, and sustainability, the company remains committed to delivering high-quality biologics to improve patient outcomes globally.

For more information about WuXi Biologics and its innovative solutions, please visit their official website.